Project Grid was a series of art prototypes, originally crafted from wood, paper, and glue, that were later transformed into bronze fine art tiles by San Francisco artist Jud Bergeron.

Traditional mold-making crushed his paper structures, making mold creation very difficult. To resolve that, I supported the artist by precisely capturing the measurements of the original art pieces using orthogonal photogrammetry.

I then built 3D replica models that were used to 3D print master patterns for bronze casting. The artist refined these 3D prints before the final pieces were subsequently cast in bronze.

Our collaboration fused tradition and technology, pushing artistic boundaries while preserving legacies.

-

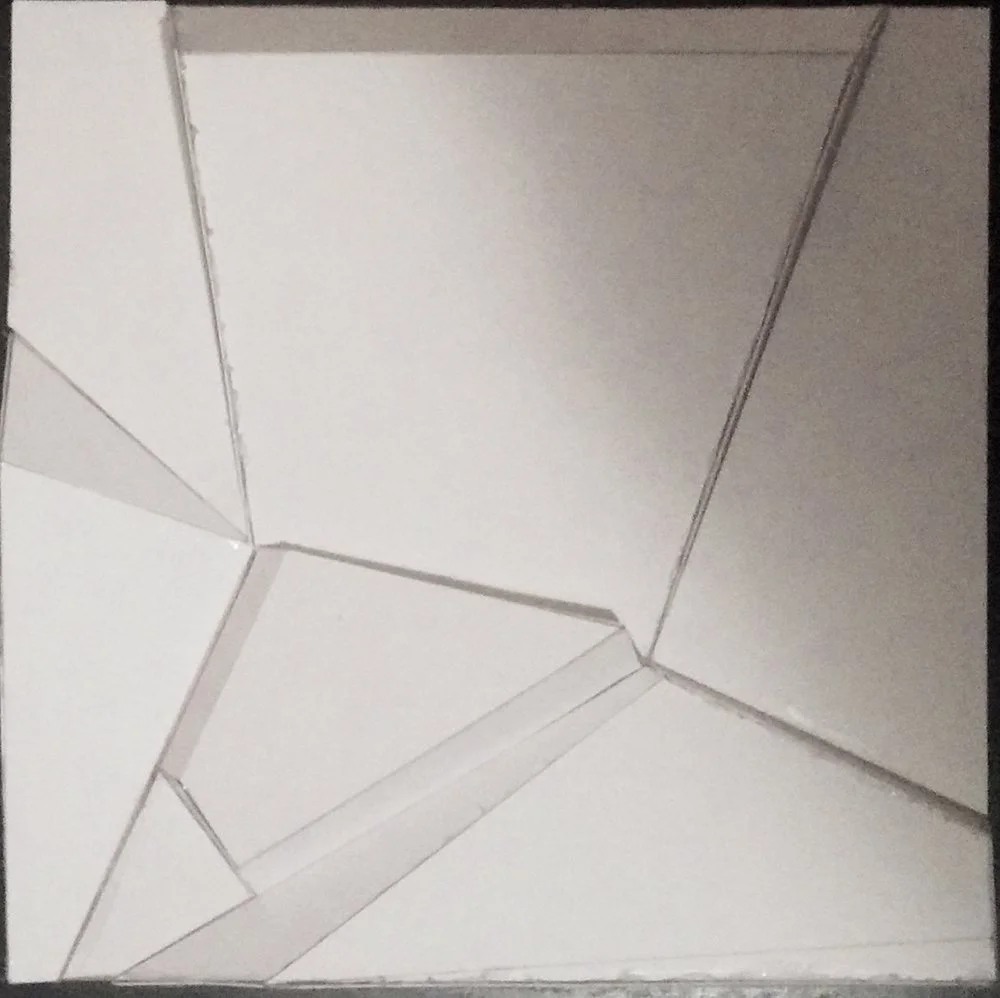

Top down photographs of Bergeron's original prototypes.

Tile #1. Poster board, glue, mounted on wood

Credit: J. Bergeron

-

Tile #2. Poster board, glue, mounted on wood

Credit: J. Bergeron

-

Tile #3. Poster board, glue, mounted on wood

Credit: J. Bergeron

-

The 3D models I built in Maya and converted to STL format.

Tile #1: 3D Model render

-

Tile #2: 3D Model render

-

Tile #3: 3D Model render

-

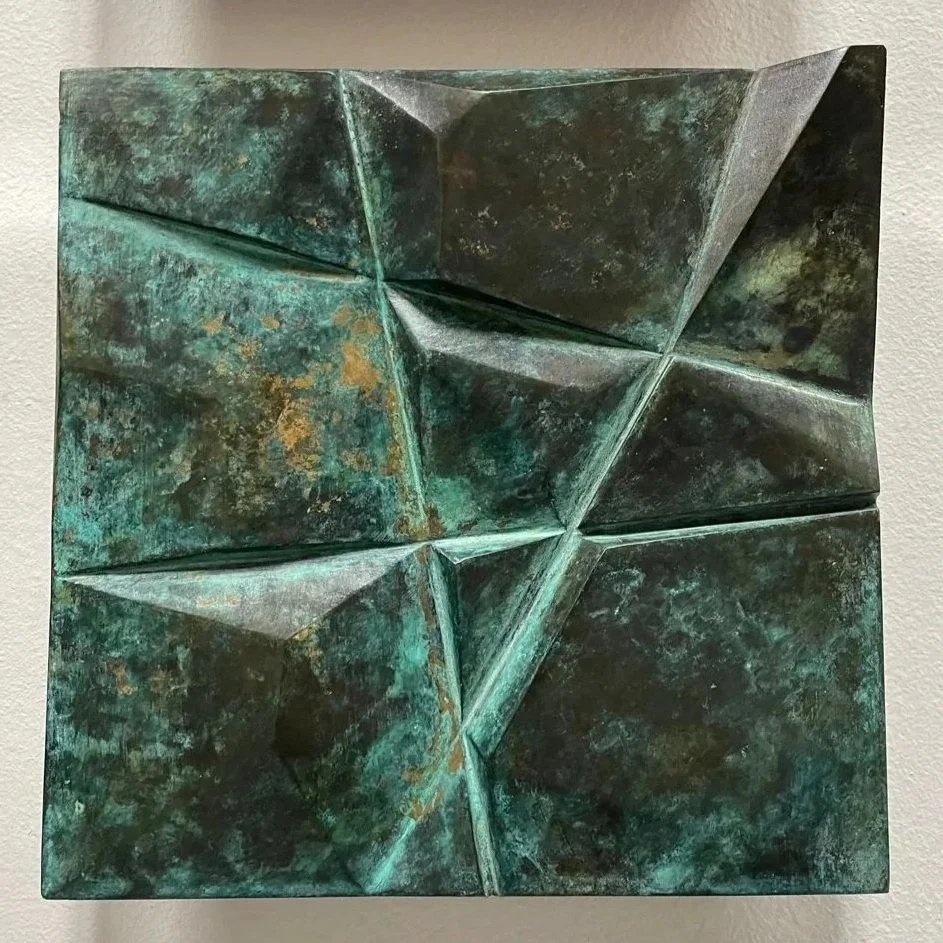

The final results cast and patinated by the artist.

Tile #1 Bronze & Patina. Credit: J.Bergeron

-

The 3D printed masters prepped by the artist.

3D prints, prepped for casting. Credit: J.Bergeron

-

The Grid layout.

Tiles with various glazes. Credit: J. Bergeron

-

The Grid layout in bronze.

Bronze tile with patina. Credit: J.Bergeron